Why are 65% of small woodworking shops using CNC routers?

Small woodworking shops have rapidly adopted CNC routers because these machines reduce production time dramatically, eliminate manual errors, and enable complex designs that were previously impossible with traditional tools. CNC technology has transformed from a luxury investment into an essential competitive advantage for modern shops.

The Automation Revolution in Small Woodworking

The woodworking industry is experiencing a fundamental transformation. Market analysis reveals that approximately 65% of small woodworking shops operate CNC routers, marking a dramatic shift from manual processes to computer-controlled precision manufacturing.

The global CNC router market, valued at $3.5 billion, continues expanding steadily. Woodworking applications account for 38% of all CNC router shipments globally, with over 2,500 routers deployed specifically for wood and signage applications in North America alone.

3 Forces Driving Adoption

Decreasing Equipment Costs: Entry-level machines now start at $2,000-$6,000

Notendavænn hugbúnaður: Modern CAD/CAM packages feature intuitive interfaces

Custom Product Demand: Consumers increasingly prefer personalized, precision-crafted items

Why Small Shops Are Investing in CNC Technology

Precision That Manual Methods Can't Match

Modern consumers expect precision and personalization. Traditional hand carving cannot maintain the sub-0.1mm repeatability that CNC machines deliver consistently across hundreds or thousands of identical pieces.

When customers order custom cabinetry with intricate joinery or furniture with complex geometric patterns, CNC viðarleið execute these designs with perfect accuracy every time.

Efnahagslegir kostir

A mid-range 4×8 foot CNC router costs between $45,000 og $80,000. However, shops consistently report that a single operator can complete work that would take 3 or 4 people working with traditional equipment.

For cabinet production shops, nested manufacturing reduces material costs significantly while cutting production time substantially. These combined savings create rapid return on investment.

The Untapped Beginner Market

While 65% of established small woodworking shops have adopted CNC technology, the beginner and hobbyist markets remain dramatically underserved. This creates an enormous opportunity.

Entry Barriers Are Disappearing

| Verðbil | Vélategund | best Fyrir | Vinnusvæði |

|---|---|---|---|

| $ 2,000-$ 6,000 | Desktop/Hobby | Beginners, small projects | 12"×12" to 24"×24" |

| $ 6,000-$ 15,000 | Entry-Level Professional | Part-time business | 24"×48" to 48"×48" |

| $ 15,000-$ 35,000 | Mid-Range Professional | Full-time business | 48"×96" (4'×8') |

| $ 50,000 + | Iðnaðar | Framleiðsla í miklu magni | 60"×120" and larger |

Modern áhugamál CNC leiðarar can handle materials from soft woods and plastics to harder species and even light metals. They occupy minimal floor space, often fitting on a workbench, making them practical for home workshops.

The Learning Curve Is Manageable

Prospective users often overestimate the difficulty of CNC operation. The process breaks down into 4 manageable stages:

1. Hönnunarfasi: Create or import 2D/3D designs using CAD software.

2. Verkfæraslóðagerð: CAM software converts designs into machine instructions.

3. Rekstur vélar: Mount material, load programs, set zero points.

4. Frágangur: Sand, assemble, and coat (familiar woodworking steps).

Experienced users consistently report achieving basic competency with regular practice. Advanced techniques like 4-axis CNC routing require more expertise, but beginners can produce profitable projects before mastering advanced capabilities.

High-Profit Applications for Beginners

Most Accessible Markets

Sérsniðin merki: Material costs remain low while markup potential stays high. Businesses, homes, and events continuously need personalized wooden signs.

Húsgögn íhlutir: Small CNC shops produce legs, panels, decorative elements, and joinery components for traditional woodworkers who lack CNC equipment.

Skápaframleiðsla:Furniture production systems can complete entire cabinet orders with minimal manual intervention.

Profitable Niche Opportunities

• Trophy and Award Manufacturing: Consistent revenue stream with minimal competition.

• Arkitektúrsmíði: Custom moldings and decorative panels command premium pricing.

• Product Prototyping: Rapid turnaround for inventors and small manufacturers.

Technology Advances Benefiting Beginners

Sjálfvirkir verkfæraskipti (ATC)

Manual tool changes consume significant production time and require constant operator monitoring. This limits machines to simpler projects using one or 2 tools.

ATC CNC beinar complete tool swaps instantly, enabling complex projects requiring 8-12 different tools to run continuously without supervision. Shops report substantial productivity increases after upgrading to ATC systems.

Hugbúnaðarbætur

Modern CNC software features pre-configured toolpath libraries for common operations. Beginners can select from proven cutting strategies, leveraging expert knowledge built into the software.

Cloud-based design libraries provide thousands of ready-to-cut projects. New users can start producing saleable products immediately while gradually learning to create original designs.

Investment and ROI Breakdown

Total Startup Costs

| Fjárfestingarflokkur | Kostnaðarsvið | Skýringar |

|---|---|---|

| CNC leið vél | $ 2,000-$ 35,000 | Depends on size and capabilities |

| CAD/CAM hugbúnaður | $ 500-$ 3,000 | Perpetual licenses or subscriptions |

| Router Bits & Tooling | $ 500-$ 1,500 | Initial collection |

| Dust Collection & Fixtures | $ 1,000-$ 5,000 | Vacuum systems, work-holding |

| Heildar stofnfjárfesting | $ 4,000-$ 44,500 | Varies by business scale |

Tekjumöguleikar

Shops focusing on high-margin custom work often recover investments faster than those pursuing volume production. A single ornamental carving project might generate $500-$2,000 in profit.

Shops with diverse capabilities, combining CNC wood routing with traditional joinery and finishing, typically build more sustainable businesses. The machine becomes one tool in a comprehensive production system.

Expanding Beyond Wood

Many wood-optimized CNC routers successfully process plastics, composites, and foam materials with minimal adaptation. This versatility enables shops to serve multiple markets.

CNC vélar úr málmi represent a different category requiring more substantial investment. Some operators successfully expand into light metal work (aluminum, brass) as their skills develop.

Stone carving machines occupy another specialized niche. Some woodworking shops diversify into memorial plaques and architectural stone elements.

Strategic Success Factors

Market Research First

Before investing in equipment, thoroughly research local and online markets. Identify specific underserved niches rather than attempting to compete broadly.

A shop specializing exclusively in custom pet memorial products faces far less competition than one offering generic wooden signs.

Analyze your target market carefully. What price points work in your area? What types of custom work do local competitors avoid? Where do customers currently source custom woodwork?

Online marketplaces like Etsy provide valuable market intelligence. Search for products similar to what you plan to produce. Examine pricing, customer reviews, and seller success rates. This research reveals market demand before you invest capital.

Education Investment

Online courses, community college programs, and manufacturer training sessions provide foundations that accelerate initial productivity and help avoid expensive early mistakes.

Many manufacturers offer comprehensive training with equipment purchase. Take advantage of these programs. The few days invested in proper training often prevent weeks of frustrating troubleshooting.

YouTube channels and online forums provide ongoing education. The CNC community actively shares techniques, solutions, and project ideas. Engage with these resources consistently.

Consider starting with free CAD software to practice design skills before purchasing equipment. This approach clarifies whether you enjoy the design process and helps identify what machine capabilities you actually need.

Incremental Growth Approach

The most reliable path involves starting with modest equipment, developing skills and customer bases, then upgrading as revenue justifies investment. This approach minimizes financial risk.

Many successful operators began with desktop machines under $5,000, validated their business concepts, then upgraded to professional equipment once revenue streams proved sustainable.

Start part-time while maintaining other income. This removes pressure to generate immediate profits, allowing focus on skill development and quality work that builds reputation.

Document everything as you learn. Which projects proved most profitable? Which customers provided repeat business? What skills required the longest development? This data guides expansion decisions and equipment upgrades.

Market Forces Driving Growth

The Customization Economy

Consumer behavior has fundamentally changed. Today's buyers increasingly reject mass-produced, identical products in favor of personalized items that reflect individual style and preferences.

This trend creates perfect conditions for small CNC operations. Large manufacturers excel at producing millions of identical units but struggle with economical custom production. Small shops with CNC equipment fill this gap perfectly.

The custom furniture market exemplifies this shift. Buyers now expect options for dimensions, materials, finishes, and design details. CNC technology makes such customization economically viable even for single-unit production.

Addressing Skilled Labor Shortages

The woodworking industry faces a critical challenge as experienced craftspeople retire. Traditional apprenticeship paths that created skilled woodworkers have largely disappeared.

CNC technology offers a solution. Complex joinery, precise dimensional work, and intricate carving no longer require decades of hand-tool mastery. Software encodes this expert knowledge, making it accessible to operators with technical skills rather than traditional woodworking backgrounds.

Community colleges and trade schools recognize this shift. CNC programming increasingly appears in woodworking curricula, creating a new generation of operators comfortable with both digital design and material fabrication.

Umhverfissjónarmið

Sustainability drives purchasing decisions for many consumers and businesses. CNC carving supports environmental goals through superior material efficiency.

Optimized nesting algorithms arrange parts on sheet materials with minimal waste. Some shops report waste reduction of 20-30% compared to traditional cutting methods. This efficiency translates directly to both environmental benefits and cost savings.

Forward-thinking shops market their CNC capabilities as an environmental advantage, appealing to eco-conscious customers willing to pay premiums for sustainably produced products.

Algengar spurningar

Is a CNC router worth it for a small woodworking shop?

Yes, for most small shops. CNC routers provide rapid ROI through increased productivity, reduced waste, and the ability to take on complex custom projects. Shops report that a single operator with a CNC can complete work that would require 3 or 4 people using traditional methods. However, success depends on having consistent work that justifies the investment.

How much does a good beginner CNC router cost?

Entry-level CNC routers cost $2,000-$6,000 for desktop models suitable for learning and small projects. For serious part-time business, budget $6,000-$15,000. Professional full-time operations typically require $15,000-$35,000 machines with 4'×8' work areas. Total startup costs including software, tooling, and accessories, range from $4,000-$45,000 depending on your business scale.

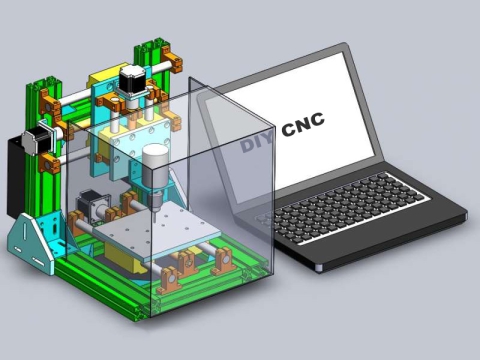

Should I build my own CNC router or buy one?

Buy one for your 1st machine. Building a CNC router requires mechanical skills, electronics knowledge, and significant time investment. Most beginners benefit more from purchasing a ready-to-run machine with manufacturer support and warranties. Consider building only if you have extensive experience and treat the build process as a learning goal itself, not just cost savings.

What software do I need for CNC routing?

You need 2 types: CAD for design and CAM for toolpath generation. Popular beginner-friendly options include VCarve Pro, Easel Pro, and Fusion 360. Many entry-level machines include basic software packages. Budget $500-$3,000 for software, though some free options exist for hobbyists.

Can a CNC router cut aluminum or only wood?

Many CNC routers can cut aluminum with proper setup. Look for machines with rigid frames, spindles rated for 18,000+ RPM, and adequate cooling systems. Wood-optimized routers can typically handle soft metals like aluminum, brass, and copper with slower feeds and lighter cuts. Dedicated metal machines are required for steel and harder materials.

How long does it take to learn CNC router operation?

Basic competency typically requires consistent practice over several weeks. Most beginners can complete their 1st simple projects within days of setup. The learning curve has 4 stages: design basics, toolpath creation, machine operation, and optimization. Machine operation itself is straightforward; design and toolpath skills develop over time with practice.

What's the best size CNC router for a small business?

A 4'×8' (48"×96") working area is the industry standard for small businesses. This size accommodates full plywood sheets and most cabinet components. However, space-constrained shops can be successful with 2'×4' or 3'×3' machines by focusing on smaller projects like signs, plaques, and component parts rather than full-sheet cabinetry.

How do I make money with a CNC router?

Focus on high-margin custom work and establish niche specializations. Profitable paths include custom signage ($50-$500 per project), furniture components for other woodworkers, architectural millwork, trophy manufacturing, and product prototyping. Combine CNC capabilities with traditional woodworking services for more sustainable revenue. Many operators leverage online marketplaces like Etsy to reach customers beyond their local area.

The Beginner Opportunity

The convergence of accessible technology, growing market demand, and evolving consumer preferences creates a genuine opportunity for newcomers to establish profitable CNC woodworking operations.

Beginners benefit from mature equipment markets offering diverse options at various price points, established supply chains for tooling and materials, abundant educational resources, and thriving online communities providing support.

At STYLECNC, we understand the challenges beginners face when entering the CNC woodworking industry. With over 2 decades of manufacturing experience serving customers across 180+ countries, we provide comprehensive solutions tailored to every skill level. From entry-level hobby machines perfect for learning the craft to professional industrial routers designed for high-volume production, our equipment lineup supports your growth journey from 1st project to thriving business.